Yeshivat Frisch Fab Lab Produces PPE for Frontline Workers

May 12, 2020

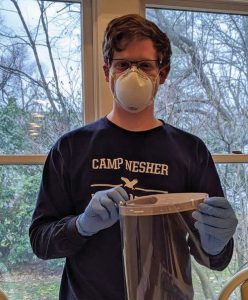

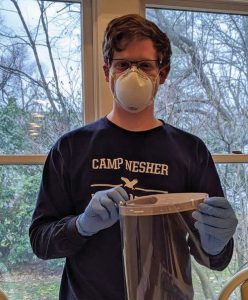

In response to the COVID-19 pandemic, students at Yeshivat Frisch spearheaded an effort to use their skills and resources to make PPE (personal protective equipment) for healthcare workers on the front lines. Students realized that some PPE parts that were in short supply at the outbreak of the pandemic could be ‘manufactured’ by desktop 3D printers—which the Frisch fab lab had at its disposal. A team of Frisch students coordinated with Frisch Engineering faculty members Travis Merritt and Michael Preston to retrieve the 3D printers from the Frisch fab lab and get to work.

In response to the COVID-19 pandemic, students at Yeshivat Frisch spearheaded an effort to use their skills and resources to make PPE (personal protective equipment) for healthcare workers on the front lines. Students realized that some PPE parts that were in short supply at the outbreak of the pandemic could be ‘manufactured’ by desktop 3D printers—which the Frisch fab lab had at its disposal. A team of Frisch students coordinated with Frisch Engineering faculty members Travis Merritt and Michael Preston to retrieve the 3D printers from the Frisch fab lab and get to work.

Originally, they printed several different models of designs, but the process was tedious, requiring an 8-hour print to produce just two head bands for face shields. More work would be needed to clean the prints, cut and attach the clear plastic visor and fasten the elastic straps. There had to be another way.

Frisch senior and engineering student Jonathan Sarasohn conducted research on other prototype ideas, and found a basic design from GimmeBuilds that did not need any 3D printed components. The design could be made with materials purchased from local stores. Sarasohn—whose brother Daniel, a freshman at Frisch, also participated in the project—engineered modifications to allow the back strap to be adjusted. With this new design, the Frisch team was able to produce 100 face shields in the time it would take to 3D print and assemble two complete units. Sarasohn developed a series of written and visual instructions that he shared on the website Instructables, so that any individuals or organizations who wish to help but do not have access to a 3D printer and laser cutter can participate in the effort to bolster the supply of PPE.

As of May 1, the team of Frisch students and faculty members had produced and donated over 270 face shield units to Staten Island University Hospital, the Teaneck and Bergenfield Volunteer Ambulance Corps, River Edge Fire Department and other locations. In addition, they have managed to produce the equipment at an impressively low cost. Originally producing the shields for $1.87 each, they recently managed to reduce the cost to just $1.24 per unit.

As of May 1, the team of Frisch students and faculty members had produced and donated over 270 face shield units to Staten Island University Hospital, the Teaneck and Bergenfield Volunteer Ambulance Corps, River Edge Fire Department and other locations. In addition, they have managed to produce the equipment at an impressively low cost. Originally producing the shields for $1.87 each, they recently managed to reduce the cost to just $1.24 per unit.

“It was meaningful to be able to use the skills I have gained through my four years in Frisch’s engineering program to work on a project that is beneficial to members of our community,” said Jonathan Sarasohn. “Additionally, this project has provided me an interesting opportunity to learn about scaling production. When we started the project, we were 3D printing a majority of the parts, which caused each shield to be expensive and time-consuming. I was able to use my experience through Frisch Engineering to combine aspects of several designs and develop a shield that could be effectively manufactured at scale.”

For Sarah Cohen, a junior at Frisch, there was also a personal reason to get involved. “Being a part of this process was extremely meaningful to me because unfortunately my grandfather was in a medically induced coma due to Covid and my family was unable to visit him,” she said. “My family and I felt helpless and this project helped me feel as though I was able to contribute and give appreciation to the staff that was taking care of him. Ultimately, we were able to deliver 100 face shields to the Staten Island University Hospital where my grandfather was being taken care of.”

For Sarah Cohen, a junior at Frisch, there was also a personal reason to get involved. “Being a part of this process was extremely meaningful to me because unfortunately my grandfather was in a medically induced coma due to Covid and my family was unable to visit him,” she said. “My family and I felt helpless and this project helped me feel as though I was able to contribute and give appreciation to the staff that was taking care of him. Ultimately, we were able to deliver 100 face shields to the Staten Island University Hospital where my grandfather was being taken care of.”

The project is ongoing.

In response to the COVID-19 pandemic, students at Yeshivat Frisch spearheaded an effort to use their skills and resources to make PPE (personal protective equipment) for healthcare workers on the front lines. Students realized that some PPE parts that were in short supply at the outbreak of the pandemic could be ‘manufactured’ by desktop 3D printers—which the Frisch fab lab had at its disposal. A team of Frisch students coordinated with Frisch Engineering faculty members Travis Merritt and Michael Preston to retrieve the 3D printers from the Frisch fab lab and get to work.

In response to the COVID-19 pandemic, students at Yeshivat Frisch spearheaded an effort to use their skills and resources to make PPE (personal protective equipment) for healthcare workers on the front lines. Students realized that some PPE parts that were in short supply at the outbreak of the pandemic could be ‘manufactured’ by desktop 3D printers—which the Frisch fab lab had at its disposal. A team of Frisch students coordinated with Frisch Engineering faculty members Travis Merritt and Michael Preston to retrieve the 3D printers from the Frisch fab lab and get to work. As of May 1, the team of Frisch students and faculty members had produced and donated over 270 face shield units to Staten Island University Hospital, the Teaneck and Bergenfield Volunteer Ambulance Corps, River Edge Fire Department and other locations. In addition, they have managed to produce the equipment at an impressively low cost. Originally producing the shields for $1.87 each, they recently managed to reduce the cost to just $1.24 per unit.

As of May 1, the team of Frisch students and faculty members had produced and donated over 270 face shield units to Staten Island University Hospital, the Teaneck and Bergenfield Volunteer Ambulance Corps, River Edge Fire Department and other locations. In addition, they have managed to produce the equipment at an impressively low cost. Originally producing the shields for $1.87 each, they recently managed to reduce the cost to just $1.24 per unit. For Sarah Cohen, a junior at Frisch, there was also a personal reason to get involved. “Being a part of this process was extremely meaningful to me because unfortunately my grandfather was in a medically induced coma due to Covid and my family was unable to visit him,” she said. “My family and I felt helpless and this project helped me feel as though I was able to contribute and give appreciation to the staff that was taking care of him. Ultimately, we were able to deliver 100 face shields to the Staten Island University Hospital where my grandfather was being taken care of.”

For Sarah Cohen, a junior at Frisch, there was also a personal reason to get involved. “Being a part of this process was extremely meaningful to me because unfortunately my grandfather was in a medically induced coma due to Covid and my family was unable to visit him,” she said. “My family and I felt helpless and this project helped me feel as though I was able to contribute and give appreciation to the staff that was taking care of him. Ultimately, we were able to deliver 100 face shields to the Staten Island University Hospital where my grandfather was being taken care of.”